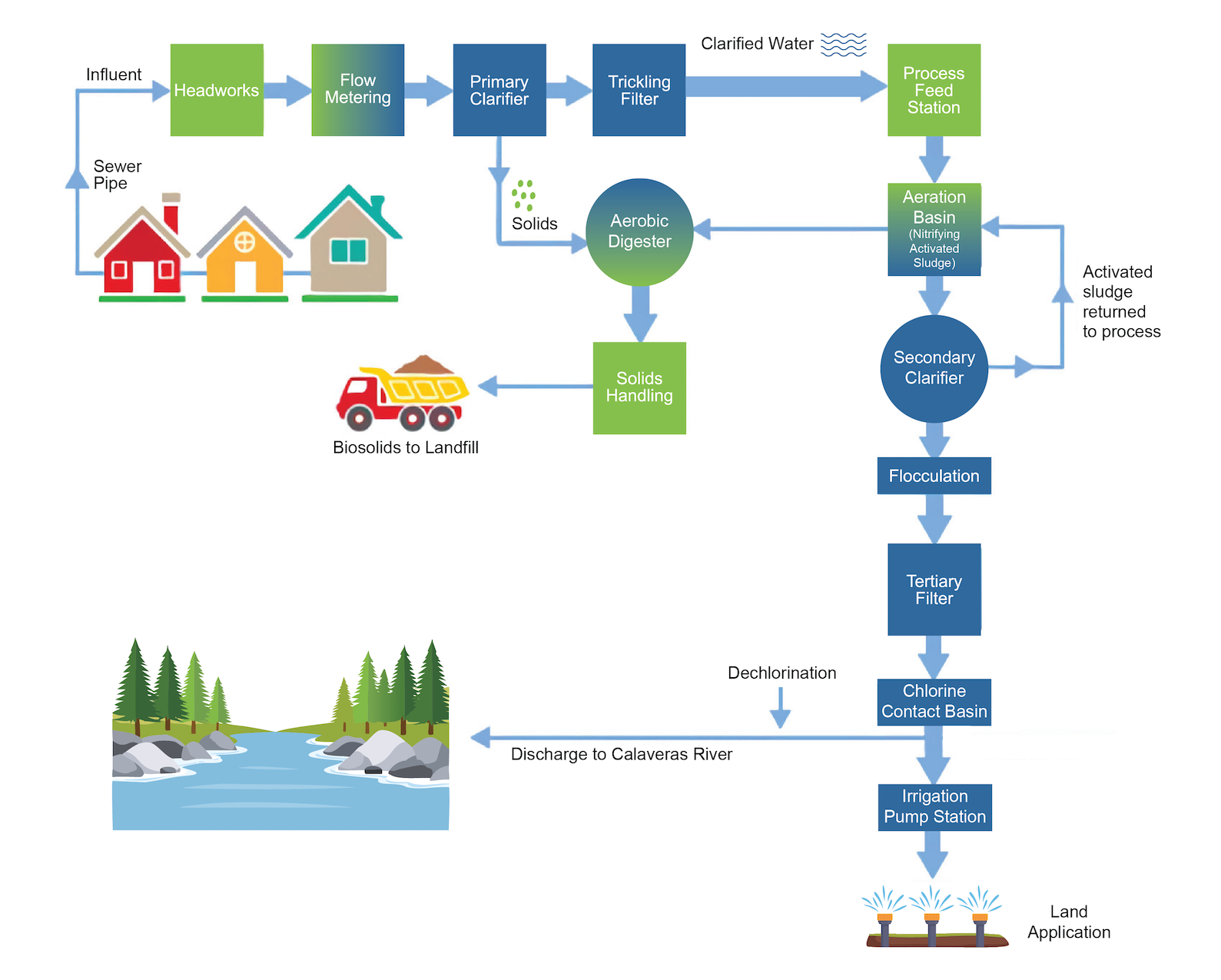

San Andreas Sanitary District’s Operators are responsible for maintaining 18.61 miles of sewer pipes or 98,249 feet. The pipeline system transports up to 250,000 gallons of raw sewage to the treatment facility daily – that equates to about 10 swimming pools of raw sewage every day! The Operators then direct wastewater through automated physical, biological and chemical treatment processes to remove all oxygen demand and all disease-causing organisms. After verification for compliance to stringent laboratory standards, the treated water is discharged to either the North Fork Calaveras River or to spray fields where the cleaned water eventually evaporates.

Hover over the graphic and click to view images and details.

Virtual Plant Tour

Headworks and Flow Metering

The Headworks receives the raw wastewater. The Headworks Auger Screen removes plastics and other debris from the waste stream. The wastewater then flows through a flume that continuously measures the flowrate of wastewater as it enters the Wastewater Treatment Plant.

Primary Clarifier

The Primary Clarifier is a “wide spot” in the waste stream that causes the water to slow down almost to a stop. The calm, quiescent conditions in the Primary Clarifier allow the solids to either settle to the bottom or float to the top. The solids are then skimmed off and pumped to Solids Handling and Digestion. The clarified water, which we call supernatant, then flows to biological treatment.

Trickling Filter

The Trickling Filter is a form of biological treatment in which naturally occurring microorganisms decompose, break down and help remove the wastes in the water. Wastewater is pumped to the Trickling Filter and sprayed through nozzles which distributes the water over a bed of plastic “honeycomb” cubes. The honeycomb gives the microorganisms a place to live with just the right conditions. By mimicking what happens in nature and providing the perfect conditions for certain microorganisms to do their work, the water is much cleaner and safer.

Aeration Basins

The Aeration Basins are a form of Biological Treatment. Billions of microorganisms are mixed with the wastewater and form Mixed Liquor Suspended Solids (MLSS). The microorganisms begin breaking down suspended solids and removing Ammonia through a process called nitrification. Since the process of nitrification requires a lot of oxygen, blowers run continuously to provide atmospheric oxygen to the microorganisms as they decompose the waste. The mixed liquor then flows on to the Secondary Clarifier.

Secondary Clarifier

The Secondary Clarifier is another wide spot in the treatment system. Solids and microorganisms from the Aeration Basins settle to the bottom of the Clarifier and are pumped back to the Aeration Basins to continue working. Floatable solids are skimmed off the water surface and pumped to solids handling facilities. The clear supernatant water then flows on to Filtration.

Tertiary Filters

The Tertiary Filters remove the tiny, suspended solids that were not captured in the Secondary Clarifier. The Tertiary Filters help ensure that the water is as clean as possible before going on to the next stage.

Disinfection

After filtration, liquid chlorine is added to the water for disinfection. This kills bacteria and other pathogenic organisms remaining in the water. The Chlorine Contact Basin gives the chlorine enough contact time with the water to fully disinfect. Once the water has made it to the end of the Chlorine Contact Basin, it is now safe to return it back to the environment.

Disposal

After disinfection, the treated wastewater is pumped to spray fields, where dozens of spray nozzles release the water back to the environment. Sometimes, during the winter months, it is necessary to discharge to a secondary location in the Calaveras River. The water is dechlorinated, and toxic ammonia is removed before discharging into the River.

Digestion

The solids that were removed from the wastewater are pumped to the Aerobic Digester. Inside, microorganisms break down the wastes, rendering them inert and odorless. The microorganisms also reduce the volume of solid wastes by converting some of them to carbon dioxide and nitrogen gas. Toxic ammonia is also removed through nitrification. Large blowers provide atmospheric oxygen to the microorganisms as they work to break down the waste.

Backup Power

The sewers do not stop when the power is out so it is important for the Wastewater Treatment Plant to always have reliable backup power. The entire plant remains fully operational during power outages thanks to on-site generators.

Irrigation Pump Station

Using advanced automation and powerful pumps, the Irrigation Pump Station moves the clean water to the Spray fields in the Designated Land Disposal Area.

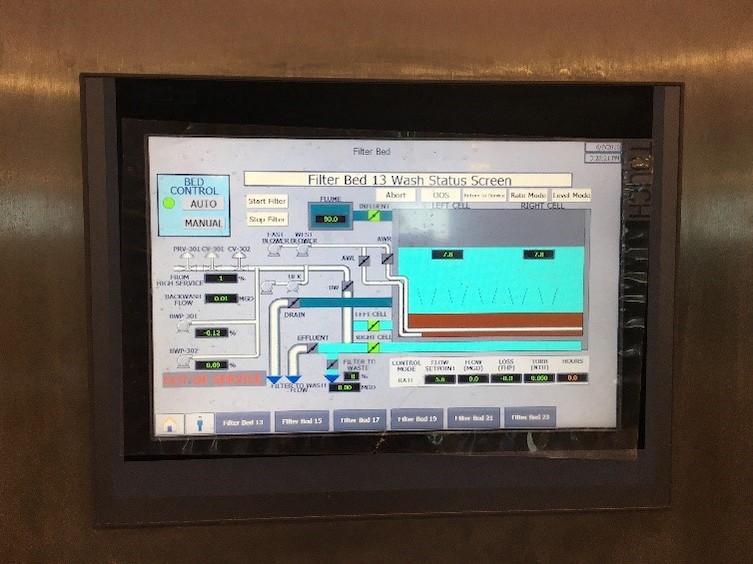

SCADA

The entire facility is controlled and monitored by an on-site Supervisory Communication and Data Acquisition (SCADA) system. Dozens of sensors and meters throughout the plant closely monitor the treatment processes and will notify the Operations Team if anything is out of normal range.

Backup Power

The sewers do not stop when the power is out so it is important for the Wastewater Treatment Plant to always have reliable backup power. The entire plant remains fully operational during power outages thanks to on-site generators.